MEDICAL METAL FABRICATION

In the medical industry, precision, reliability, and safety are critical in every component. Mid-Atlantic Steel Fabrication provides expert medical fabrication solutions that meet the stringent requirements of the health care industry. Our advanced metalworking techniques and comprehensive fabrication process enable us to produce durable and compliant parts.

Our Custom Medical Metal Fabrication Capabilities

We specialize in creating custom components for the medical sector through a blend of cutting-edge technology and skilled craftsmanship. Our process covers every step, from the initial design to the final assembly and delivery. Our capabilities include:

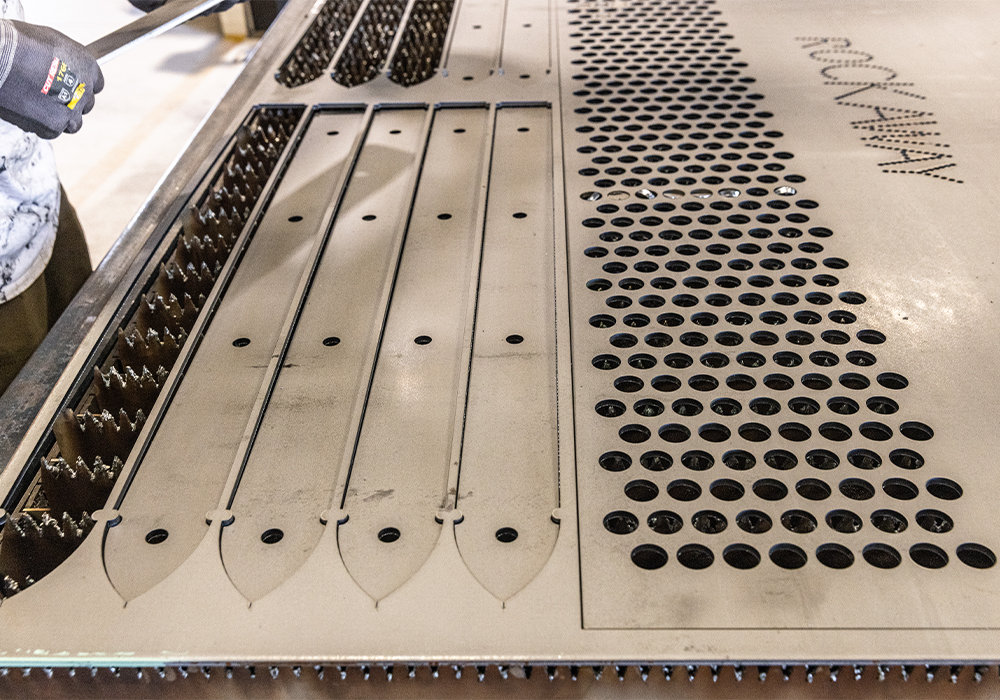

- Laser cutting: We use advanced laser systems that provide precise, clean cuts in various metals. Laser cutting allows us to handle complex geometries and achieve intricate shapes with high accuracy, making it ideal for producing delicate medical components.

- Metal cutting: Using tools like the HYDMECH S-20A band saw, we achieve seamless cuts essential for the high quality standards demanded in medical applications.

- Welding: Our welding experts use MIG and TIG welding techniques to join metal components, delivering strong, reliable joints for parts that endure demanding medical environments.

- Metal bending and stretching: We use state-of-the-art CNC machinery to perform accurate bending and stretching operations. This technology allows us to achieve exact angles and repeatable results.

- 3D CAD design: Our design team leverages advanced computer-aided design software to optimize every detail of your component.

- Powder coating: As an optional finishing process, we apply high-quality powder coating to enhance corrosion resistance and provide a smooth, attractive surface on fabricated parts.

- Additional services: We provide additional services such as tapping, countersinking, and hardware insertion, enhancing the functionality and integration of your components.

Common Materials in Medical Fabrication

Selecting the right material is crucial in medical metal fabrication, as it affects the part’s performance, safety, hygiene, durability, and compliance with medical regulations. We work with a range of medical-grade materials:

- Steel: Stainless steel is a favored material in the medical field due to its strength and corrosion resistance. Specifically, stainless steel 316 is commonly used because it withstands high temperatures and harsh sterilization processes while maintaining a polished, hygienic surface. This material is ideal for components such as surgical instruments, medical carts, and electronic device housings.

- Aluminum: Aluminum is another key material used in medical sheet metal fabrication. Its lightweight nature and excellent formability make it well-suited for applications requiring precision and ease of handling. Aluminum 5052 is particularly popular in medical fabrication due to its weldability, rust resistance, and consistent performance under repeated use. This metal is often used to produce portable medical devices, equipment enclosures, and diagnostic instrument frames.

- Additional metals: Depending on a project’s specific requirements, we also work with other specialty alloys and metals. Our fabrication process can incorporate materials that provide unique benefits, such as enhanced biocompatibility or improved durability. Contact us for more details.

Metal Applications for the Medical Industry

Our fabricated metal parts are integral to a wide range of medical applications, including:

Medical Carts

Custom carts are essential for transporting medical supplies and equipment in hospitals and clinics. We produce durable and functional carts that are easy to clean and sterilize.

Enclosures and Housings

We fabricate enclosures for medical devices, such as diagnostic equipment and other sensitive medical devices. We use corrosion-resistant materials that meet safety standards.

Hospital Furniture

Our experience enables us to fabricate robust, durable, and safe hospital furniture, including beds, chairs, wheelchair frames, and stands for patient and medical staff use.

Why Choose Mid-Atlantic Steel Fabrication for Medical Fabrication?

Here’s why medical companies choose us for their medical sheet metal needs:

- Experienced team: Our D1.1 structural certified fabricators have extensive experience working with medical-grade materials and delivering components that meet the highest quality and precision standards.

- Comprehensive in-house capabilities: We perform most fabrication in-house, allowing us to maintain strict quality control throughout every production stage. Our extensive capabilities enable us to handle projects of any size or complexity with precision and efficiency.

- Advanced technology: We invest in state-of-the-art equipment, including CNC machines, laser cutters, and welding technology, to deliver components with the exact specifications required for your project.

- Regulatory compliance: Our fabrication process adheres to the strict quality standards demanded by the medical industry. Each component undergoes rigorous inspection to meet all relevant certifications and performance criteria.

- Personalized service: A dedicated project manager oversees your project from start to finish, aligning every detail with your expectations. This personalized approach results in custom solutions that fit perfectly within your product’s design and function.

- Fast turnaround times: Our efficient production processes allow us to meet urgent medical industry demands while maintaining high quality standards.

Contact Us Today for Custom Medical Fabrication Services

Our focus on precision, cutting-edge technology, and personalized service has made Mid-Atlantic Steel Fabrication a trusted partner for custom medical sheet metal fabrication. We deliver products that combine technical excellence with practical performance, enabling your components to perform reliably in critical medical applications. Contact us online for a quote or call us today at 717-687-7313 to discuss your medical fabrication requirements.